The test bench works by imposing by way of a hydraulic system a motion to a load cell to which the test specimen is rigidly attached. By that the dynamics of the remaining drive train change significantly.

We Design And Manufacture Engine Test Benches Component Test Beds And Steering Test Beds

This dynamic behavior is mainly determined by the rotors inertia which due to its size has to be dismounted for System Test Bench tests.

. The small high-speed motor test bench test system is used to test low-power high-speed motors mainly for the low-power aviation generators robot motors small high-speed compressor motors machine tool spindle motors etc. Of a vehicle engine. An engine test bench is utiliezed to execute a performance test durability test and etc.

CN-105444949-A chemical patent summary. Has not to be carried out on a vehicle submitted for type approval if the braking system components are tested on an inertia test bench to meet the prescriptions of annex 4 paragraphs 152. This work presents a new systematic solution to identify the vehicle inertia parameters which are essential inputs for vehicle simulation and vehicle safety research.

Nowadays inertia dynamometers or roller dynamometers are used for the development and testing of vehicle brakes. Base frame with air springs and DUT mount in a vibration-optimized design as special requirement for high speeds. Flywheels resist changes in rotational speed by their moment of inertia.

Download Citation Inertia compensasion control of engine test bench An engine test bench is utiliezed to execute a performance test durability test and etc. In order to still operate the WTG controller without modifying it and to allow for representative load analysis a Hardware-in-the-Loop HiL Controller needs to reproduce the. Safe distance between the maximum speed and the first natural system frequency.

Perfect test system and good test facility are the premise and the foundation to guarantee the product qualityIt can improve research and develop level elevate brake technical and develop friction material theory according to the research of automobile detent inertia test. The brake disc clamping device comprises a motor and a brake force arm rod wherein the motor is connected with a group of inertia discs the inertia discs are connected through a main shaft the main shaft is supported through a support frame the main shaft is connected with a brake disc. The Type-I test according to annex 4 paragraph 15.

Send Enquiry Product Details Product content introduction. Figure 1 shows a typical mechanical configuration of the engine test bench. Скачать версию для Windows.

In conceptual design phase of this work a virtual three Degree-of-Freedom DoF test bench parallel manipulator PM whose moving platform is used to clamp vehicle under test is developed. 1 simulation working condition inertia experiment bench and an experiment method. Electric motor test benches.

Translations in context of inertia test in English-Russian from Reverso Context. 12 Simulating acceleration component The idea of making this test bench is based on emulating an actual vehicle load on the test bench. Download scientific diagram The moment of inertia test bench.

The installation platform can be designed according to the motor to be tested and the end flange installation. To make the engine an idling state a dynamometer must be controlled so that the engine becomes no-load state. Identification and Robustness Analysis of Powertrain Excitation Forces.

Зарегистрироваться Войти Войти через Facebook Войти через Google. Of the brake assembly of various types of vehicles. The inertia parameters are evaluated by measuring the specimen motion law together with forces and torques that the test specimen transmits to the motion system through the load cell.

Inertia flywheel is a mechanical device specifically designed to efficiently store rotational energy. As in the figure for acceleration resistance vehicle inertia and wheel inertia. Dynamic Brake Test Stand.

Brake Inertia Dynamometer The brake inertia dynamometer can be used to test the pre-run-in inspection running-in test efficiency test benchmark test thermal decay recovery test brake liningpad wear test parking brake test etc. However these testing methods are either entirely unable to simulate dynamical conditions close to real driving maneuvers or they can do so approximately only at very high costs. Rotor inertia emulation inertia simulation rotational impulse control hardware in the loop wind energy ground testing nacelle test bench drive train test bench 1.

INTRODUCTION Wind Turbine Load Application System The amount of world wide. In these tests there is a process that the engine must become an idling state. The automobile detent is essential equipments relate to the traffic safety whose quality is very important.

Compact load machines with low mass moment of inertia and highly accurate speed and torque measurements. Torque τ is measured by the product of flywheel moment of inertia and rocorded flywheel angular acceleration. An experimental verification of the method was conducted at the world-wide first nacelle test bench.

Test Bench For Rotor Blade Testing A 2 Maxon Ec 45 Flat 30 W Motor Download Scientific Diagram

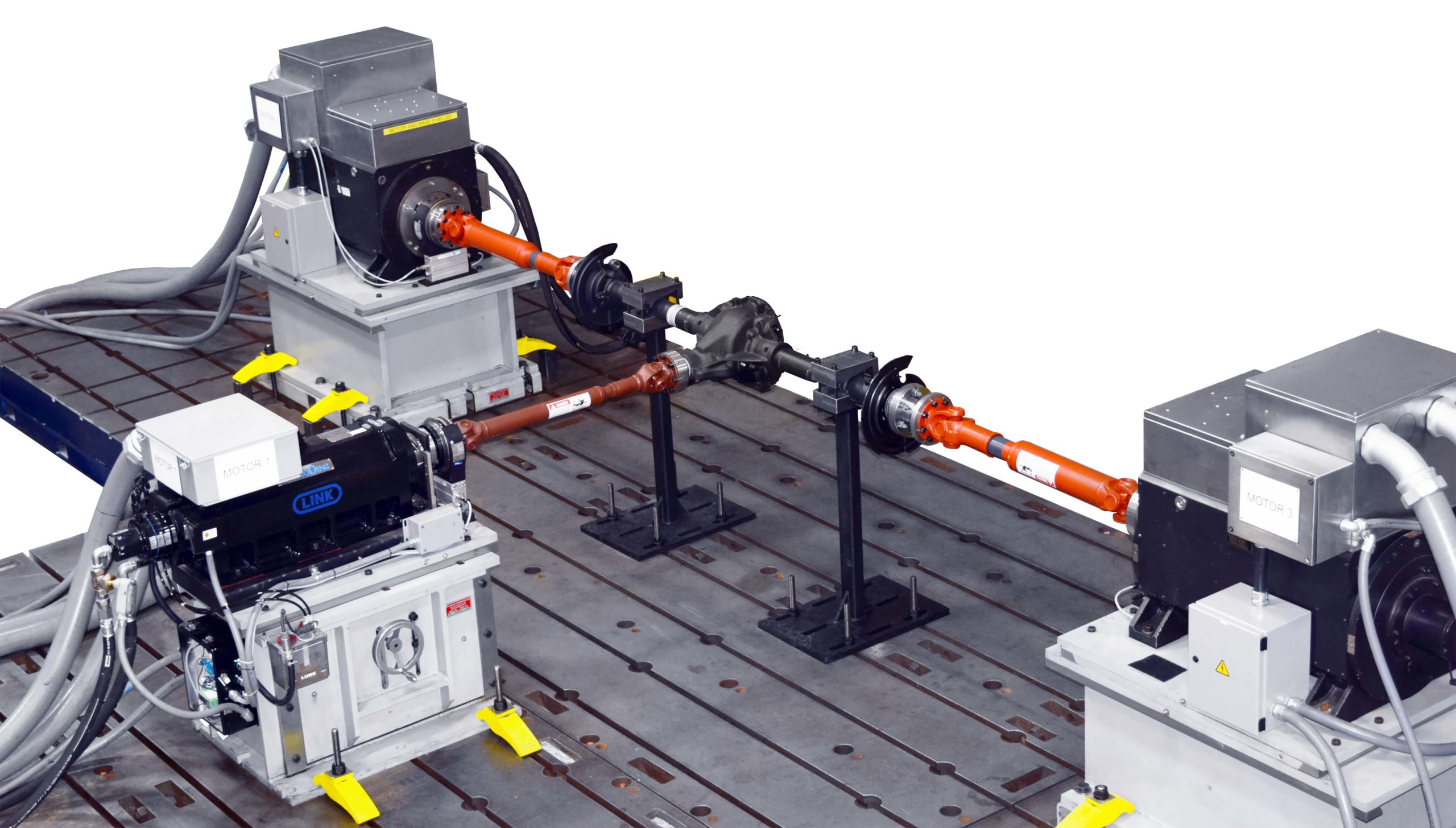

Link Engineering Equipment Testing Support E Mobility Enhanced Driveline Test System T Rig

Measurement And Testing Equipment Klotz Gmbh

Bench Test For The Powertrain Bench Test For The Powertrain Download Scientific Diagram

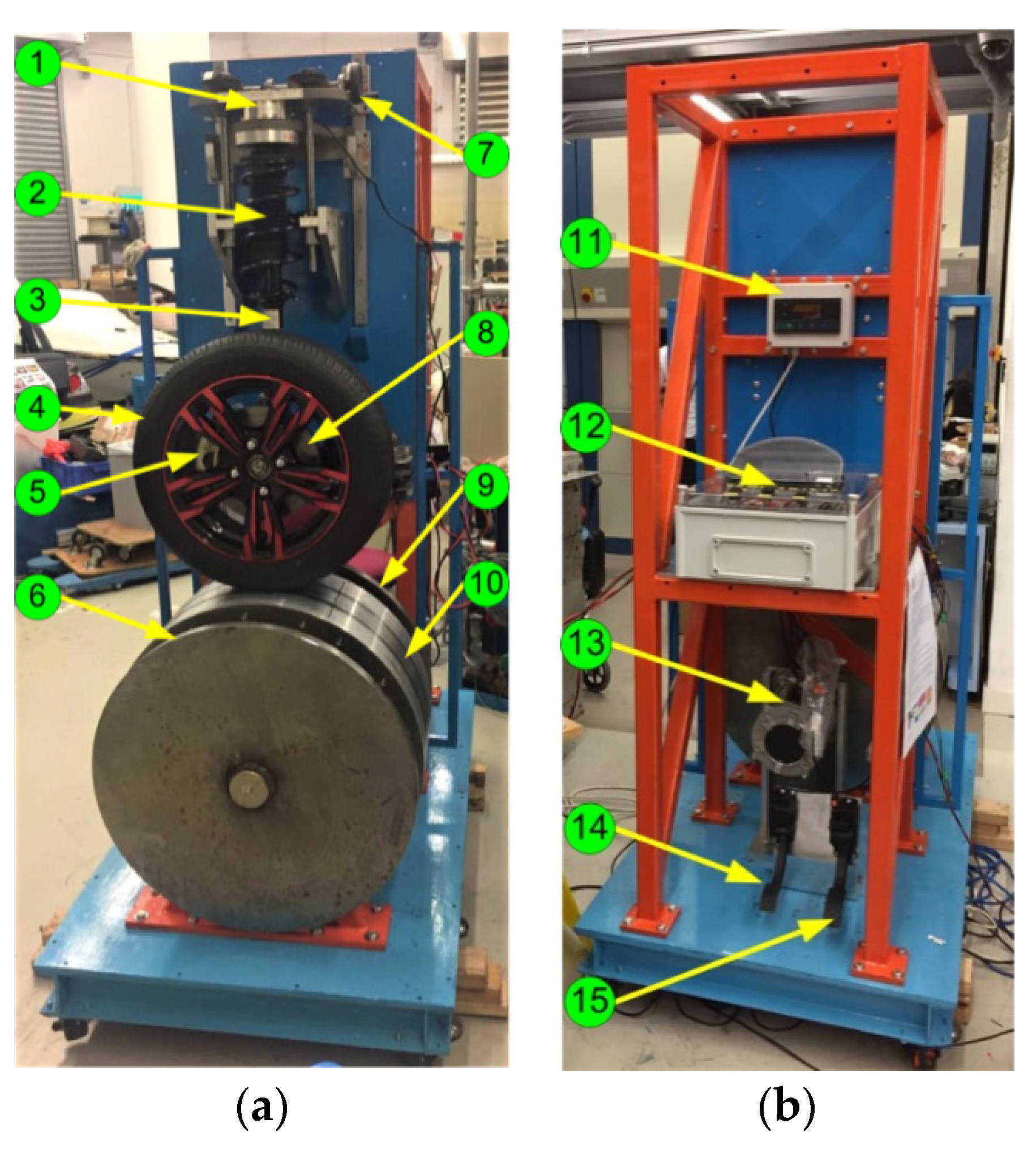

Energies Free Full Text Design Analysis And Application Of Single Wheel Test Bench For All Electric Antilock Braking System In Electric Vehicles Html

Heavy Duty Scissor Lift Tables Capacity 500kg To 1250kg Scissor Lift Lift Table Heavy Duty Scissors

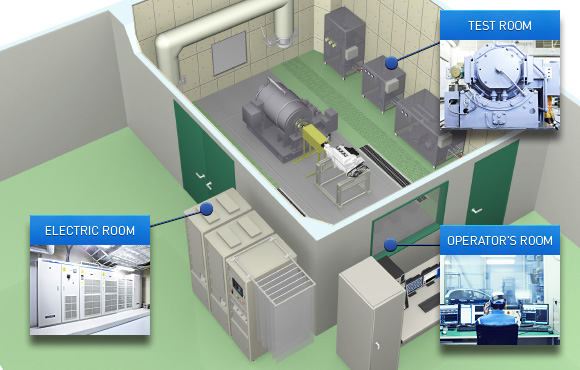

Engine Bench System Testing Systems Meiden Europe Gmbh

Sil Testing Test Bench Software Hil Test Bench

Test Bench Test Bench Products Liedtke Antriebstechnik Gmbh Co Kg

System Mounted In The Second Test Bench Download Scientific Diagram

Measurement And Testing Equipment Klotz Gmbh

Fahrzeugtechnik Forschung Ausstattung

We Design And Manufacture Engine Test Benches Component Test Beds And Steering Test Beds

We Design And Manufacture Engine Test Benches Component Test Beds And Steering Test Beds

Motor Test Bench Talks The Torque Hackaday